actware LPS

Line Performance Software

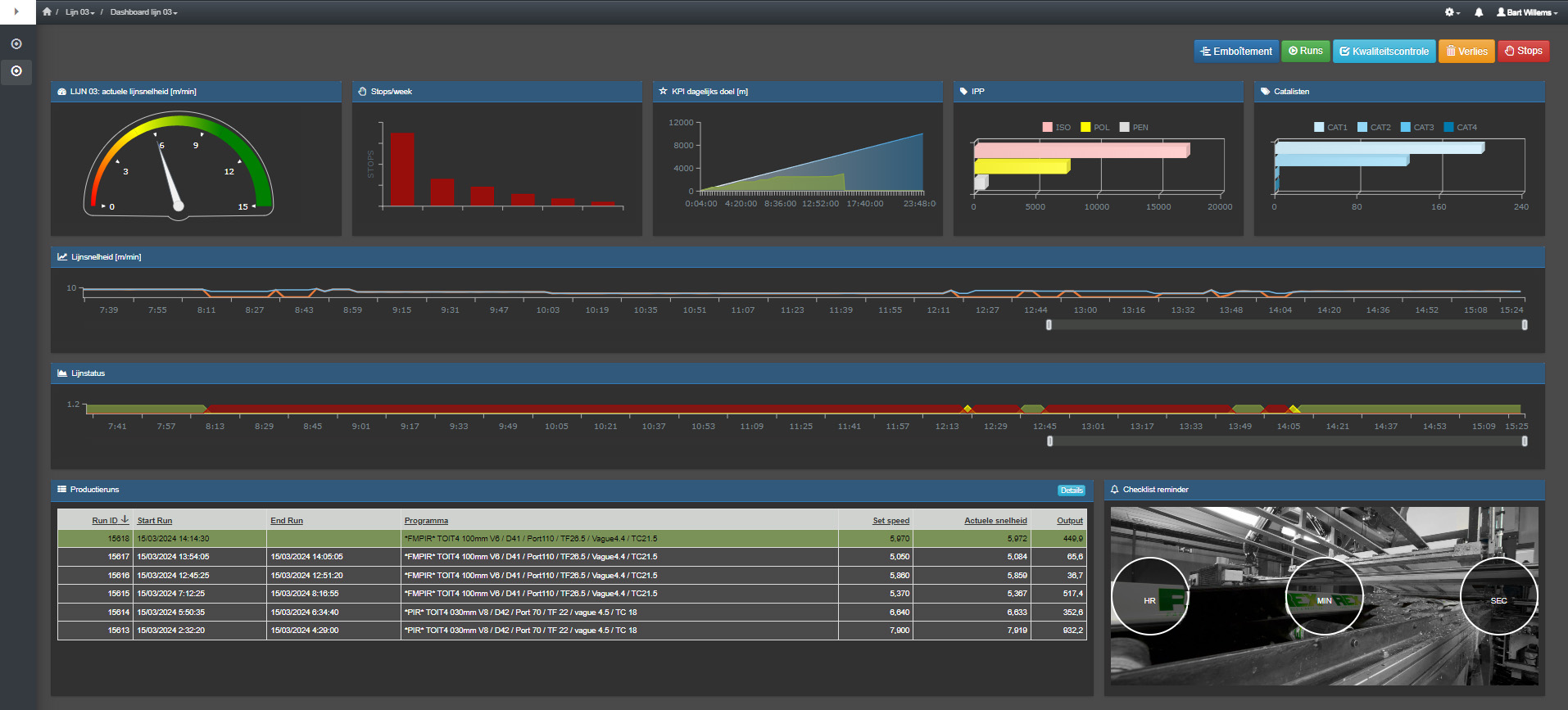

The time when machines work as stand-alone units is over. Data communication with ERP software, logging systems and analysis software have become unthinkable in today's Industry 4.0. BFP develops software that captures and analyzes production data and reports the efficiency of the production process in real time. An indispensable tool for actual costing and online production monitoring, for the operator, the process engineer and the operational management.

actware LPS provides the ability to create operational expertise by collecting and analyzing realtime production data.